Product Center

Manufacture and repair of metallurgical and mining equipment, production of various types of riveted and welded parts

Company establishment

Technical Team

Footprint

Industry experience

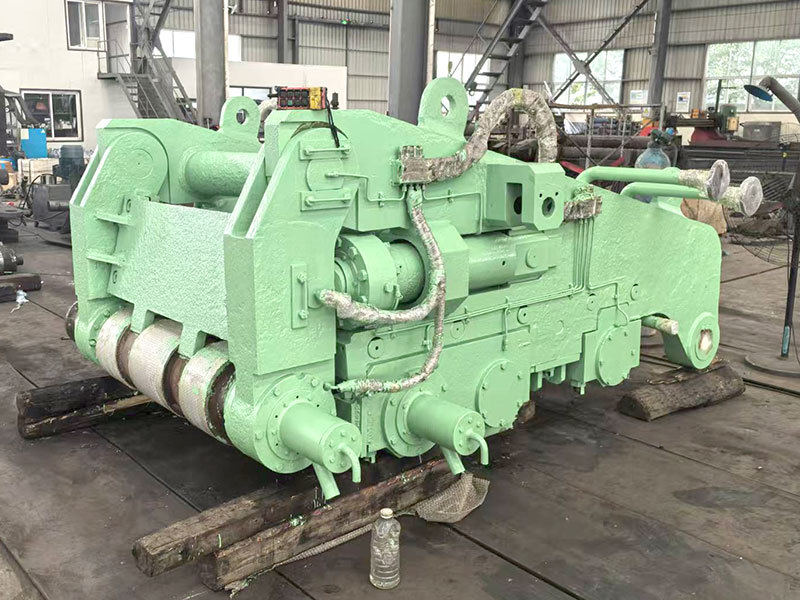

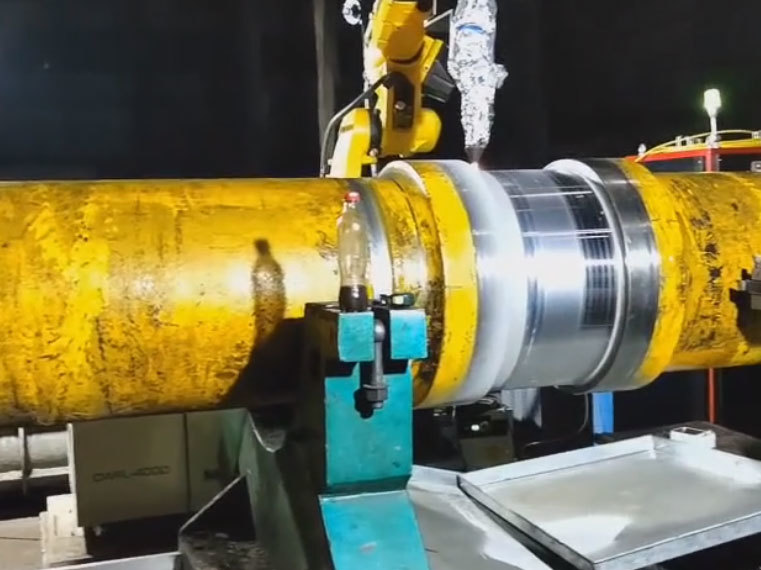

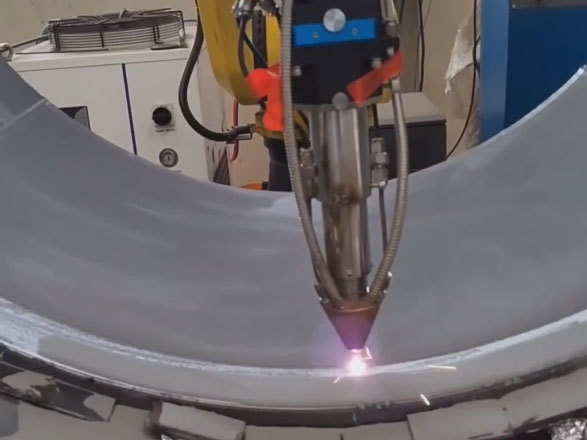

Production of various types of riveted and welded parts, laser cladding, laser alloying to prepare new production, remanufacturing of key structures and components

01

WHO WE ARE?

Tangshan Fangtong Metallurgical Equipment Manufacturing Co.

02

WHAT WE CAN DO?

Engaged in the manufacture and repair of metallurgical and mining equipment

Fangtong Metallurgy

Manufacturing and repair of metallurgical and mining equipment

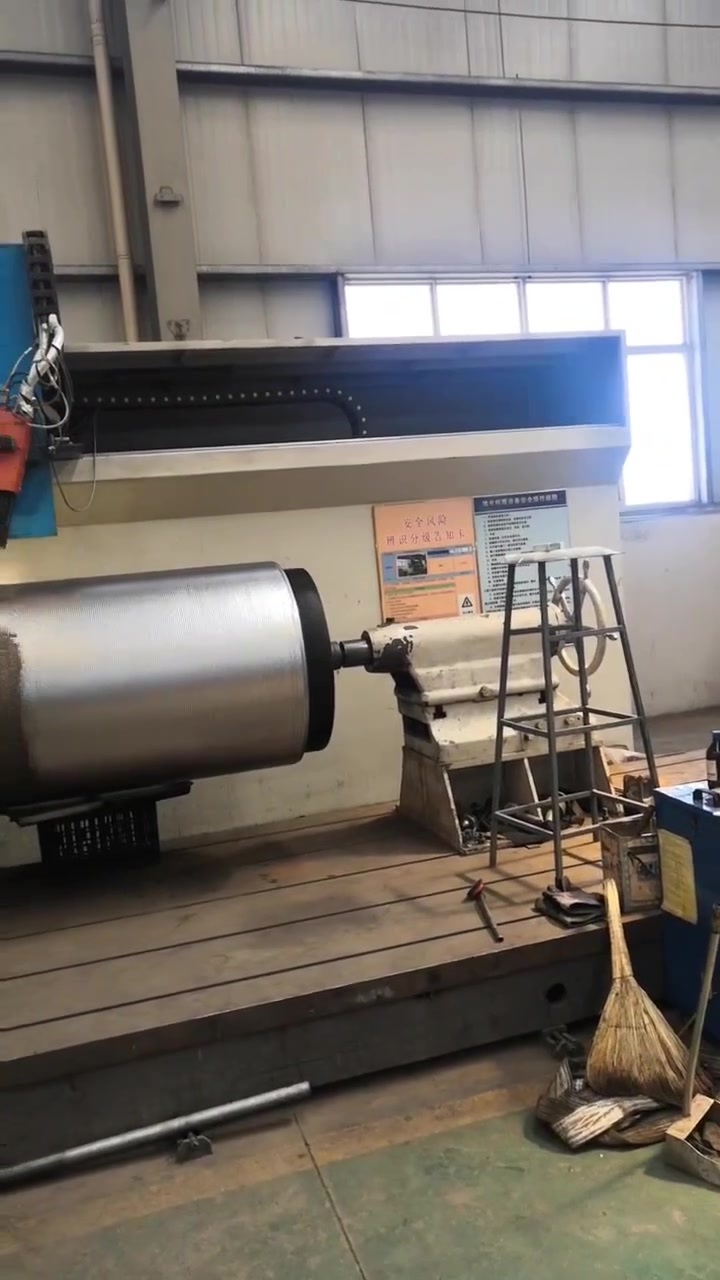

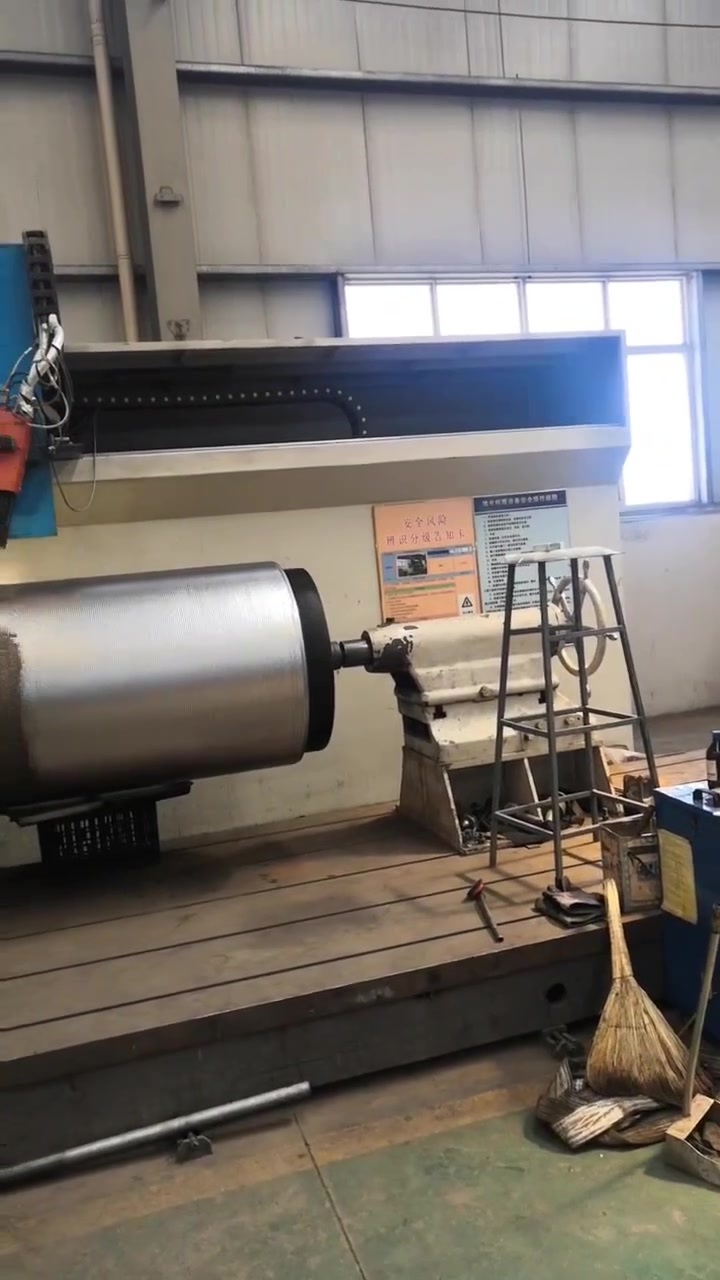

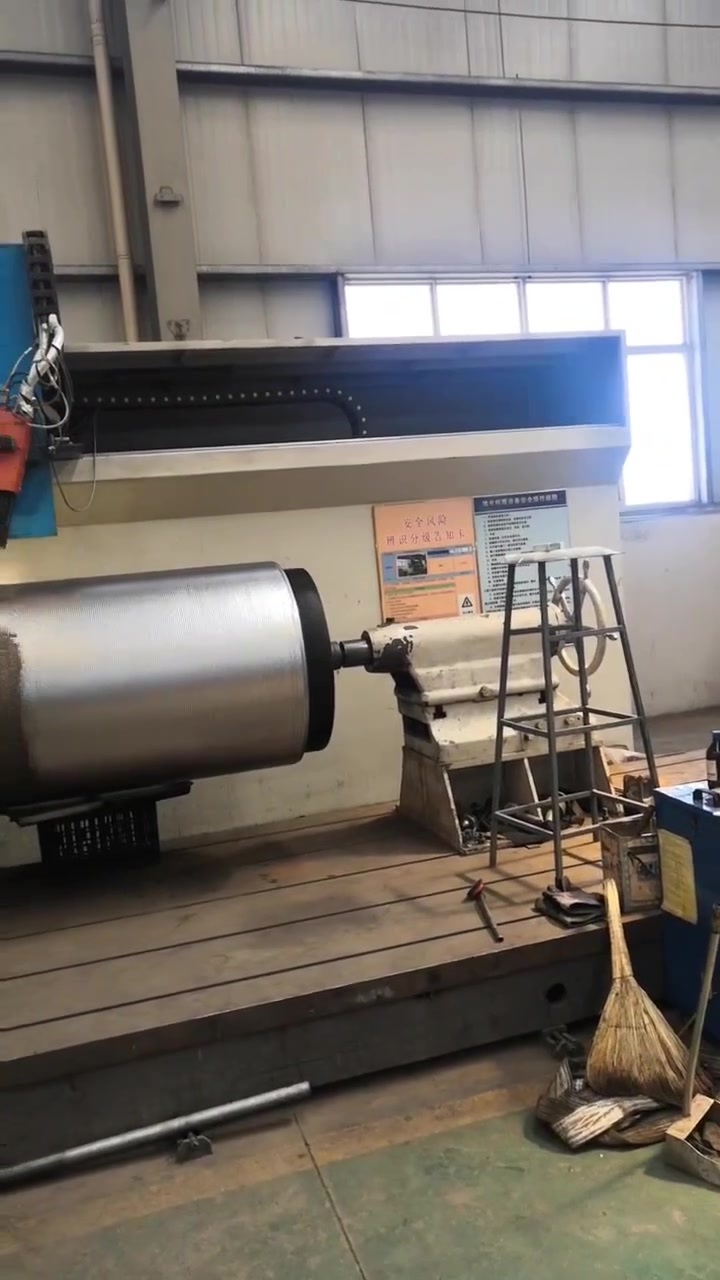

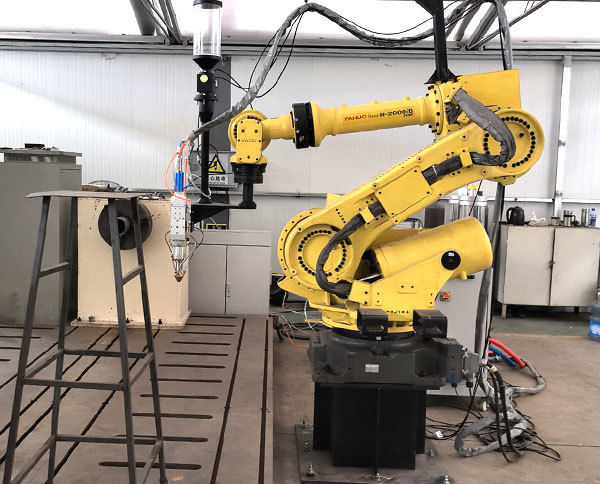

The company was founded in 2006 with a registered capital of 30 million RMB. It mainly focuses on machining and laser cladding. The company has always been adhering to the integrity management, quality first development concept and customer first, technology first development strategy. The company is located in Fengnan District, Tangshan City, small set of industrial area covers an area of more than 50 acres, more than 100 employees, annual sales of 50 million yuan. At present, the company has a variety of high-end equipment such as laser cladding equipment, CNC gantry machining centers, CNC lathes, machining centers, etc. The products include laser cladding, laser additive remanufacturing, metal surface hardening, surface machining, production of metallurgical equipment, large-scale riveting and welding processing. And we will become a national high-tech enterprise in 2019 2024.

CASES

Manufacture and repair of metallurgical and mining equipment, production of various types of riveted and welded parts

Case Test Information

Case Test Information

Case Test Information

Case Test Information

WHY CHOOSE US

The main application areas cover mining machinery, coal mining machinery, metallurgical equipment, ceramic industry, aerospace, defence and military industry, chemical equipment, automotive, shipping and nuclear power industry.

Technical Strength

New and remanufactured products based on new materials with excellent resistance to wear, corrosion and high temperatures

Technical Team

The company has a production technology team of 50 people, with many technical titles and related professional engineers and technicians

Product quality

With advanced processing equipment and strong scientific and technological strength, we develop stable performance and more applicable metallurgical products.

Customers say to us

Listening to the Voice of the Customer

Hear directly from our customers

At present, the enterprise has a production technology team of 50 people, with 2 sets of high-power semiconductor laser cladding complete sets of equipment, 1 set of continuous fiber laser complete sets of equipment, and equipped with 3 sets of large-scale CNC gantry milling machine, 8 sets of machining centers and CNC lathes, 20 sets of grinding, milling and other machining equipment;

Clients in Moscow

At present, the enterprise has a production technology team of 50 people, with 2 sets of high-power semiconductor laser cladding complete sets of equipment, 1 set of continuous fiber laser complete sets of equipment, and equipped with 3 sets of large-scale CNC gantry milling machine, 8 sets of machining centers and CNC lathes, 20 sets of grinding, milling and other machining equipment;

Liaoning Customers

BLOG

News & Media

Nov 21,2019

Sep 23,2019

Laser cladding wear resistance test

May 08,2023

What are the more common crushing processes in mineral processing plants?

Apr 13,2023

Roll Crusher Performance and Usage

Need help to find the right solution with our experts?

For inquiries about our products, please leave your E-mail and we will be in touch within 24 hours.