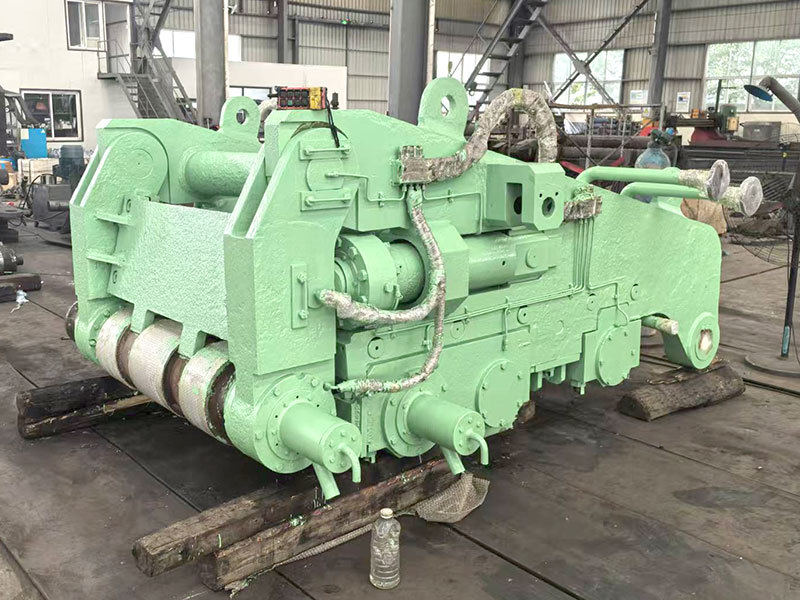

Re-manufacturing continuous casting rolls using high-power semiconductor laser cladding and advanced alloy powders not only reduces production costs for steel mills but also significantly shortens the downtime for roll maintenance, resulting in considerable economic benefits. This new technology for repairing continuous casting rolls offers significant advantages, extending service life to more than double that of submerged arc welding repair, and has already been industrialized.

Laser cladding remanufacturing of continuous casting rolls offers the following properties:

◆ Excellent resistance to high-temperature oxidation and tempering softening;

◆ Good resistance to stress corrosion;

◆ Resistance to localized pitting corrosion and crevice corrosion;

◆ Low coefficient of thermal expansion, resistance to thermal fatigue;

◆ Excellent resistance to mechanical fatigue;

◆ High hardness and resistance to abrasive wear and adhesive wear;

◆ High strength and toughness.

Through metallurgical high-power semiconductor laser cladding remanufacturing technology for continuous casting rolls, major technical challenges difficult to overcome in metallurgical production have been successfully solved, significantly reducing production costs and improving the utilization efficiency of continuous casting equipment.

TAG:

Laser cladding remanufacturing and strengthening of continuous casting rolls

Contact Us

Classification